The purpose of this lab is to change from manual to open loop control of the car. The PCB for manual control is cut off and placed with Artemis, the motors are controlled using two motor driver with PWM signals sent from Artemis pins. At the end of this lab, the car is able to execute a pre-programmed series of moves, using the Artemis board and two dual motor drivers.

Prelab

Motor Driver Connection

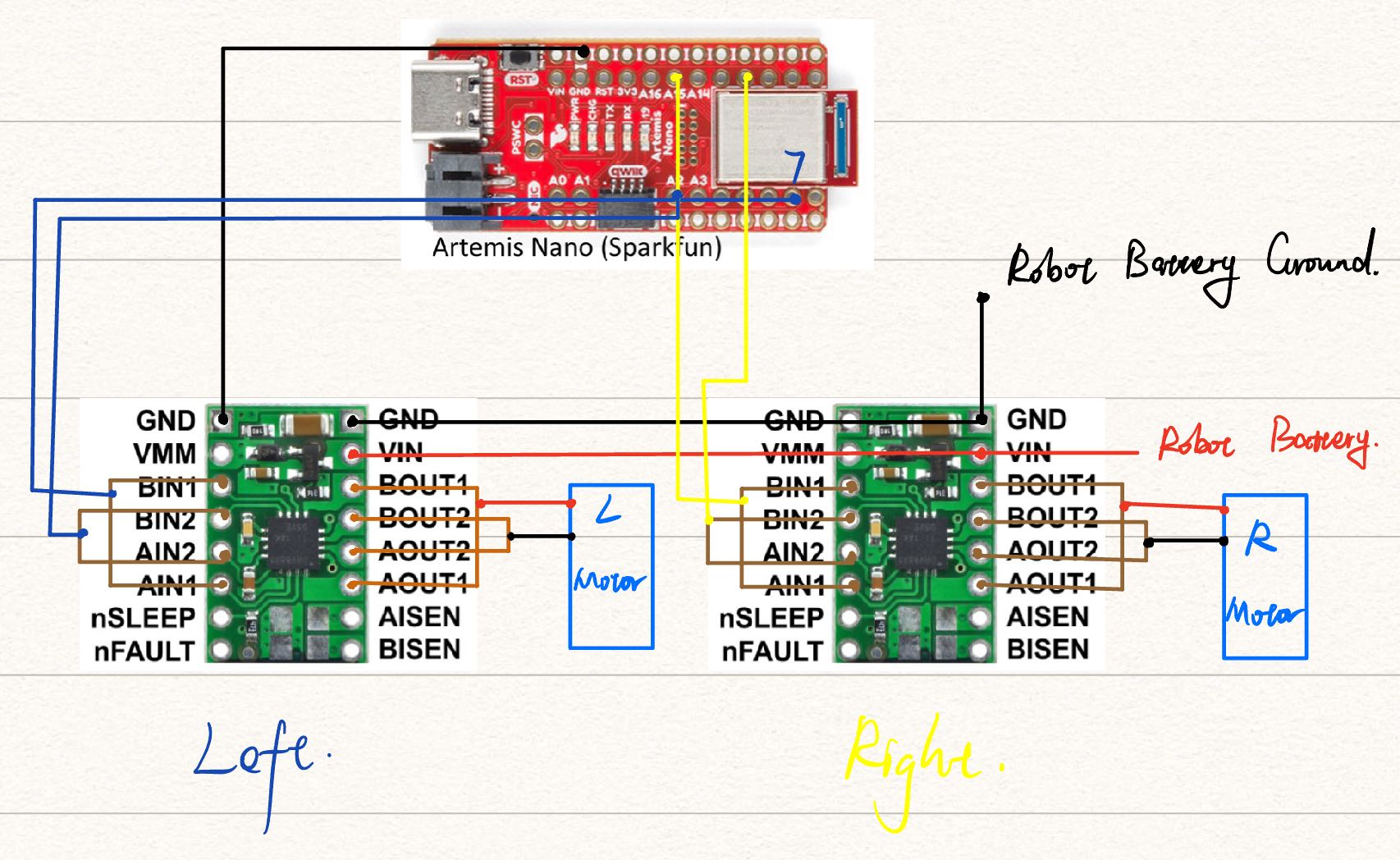

The diagram below shows how I finally connect the whole systems includig Artemis, two motor drivers, motors and batteries.

It is noticed that the inputs and outputs of each dual motor driver are parallel-coupled, so that we can deliver twice the average current without overheating the chip. The Artemis pins to generate PWM signal to input of motor driver are decided unfortunately by accident after I ruined some of the contiguous pins... But they work as expected eventually.

Battery Discussion

The Artemis and motors are powered using different batteries since Artemis uses much less current while motors consumes a lot. Therefore, the 3.7 V,850 mAh battery with greater energy capacity is used to power the motors, while the 3.7V,650 mAh battery is used to power Artemis.

Lab Tasks

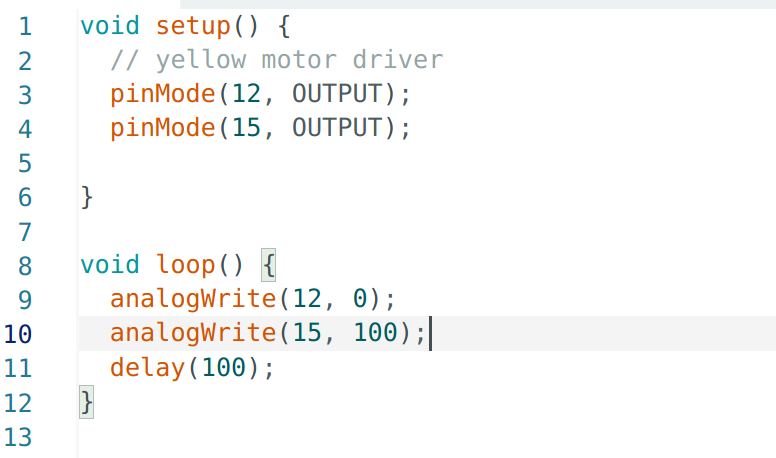

Single Dual Motor Driver

After soldering the inputs and outputs of one motor driver in parallel, I soldered A15 pin from Artemis to connect with BIN2 & AIN2 of the motor driver. I sodered wires on the Ground and Vin pin of the motor driver, so that it can be powered by external power supply using 3.7V voltage (since the battery used to power the motors is 3.7V). Then I write code to generate PWM sigals from A15, send them to motor driver and connect oscilloscope with BOUT2 & AOUT2 pins to verify the output from motor driver.

The video below shows how I connect the components and measure the output signal using oscilloscope.

I used analogWrite to define a PWM signal, where, according to this documentation, the parameter that sets the duty cycle is an 8-bit unsigned integer, i.e.a value in the range 0 ≤ PWM_out_level ≤ 255. I set 100 to pin A15 which represents around 100 / 255 = 39% duty cycle.

Spinning Wheels

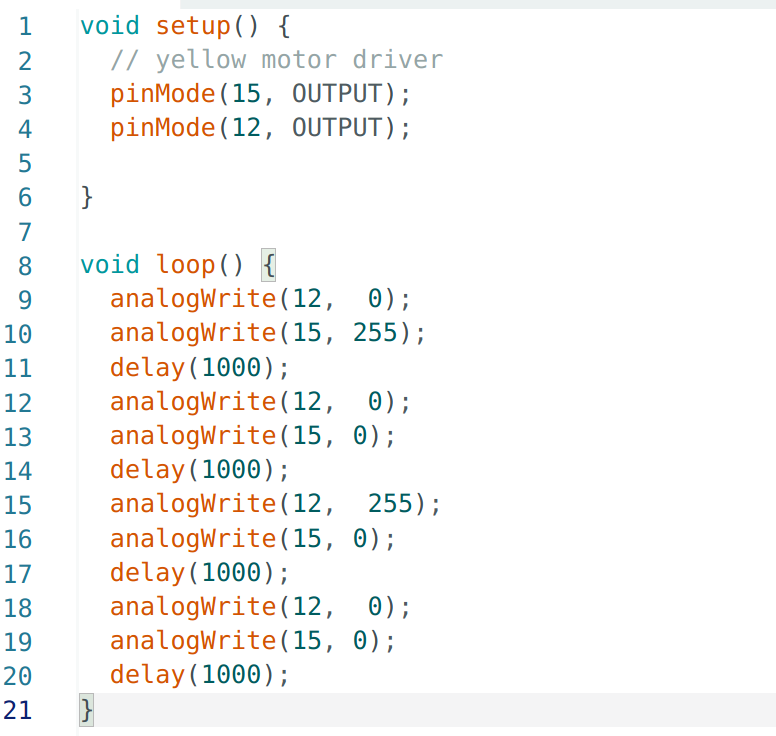

After verifying the connection and outputs, I disassemble the car, cut the wires connecting motors with the factory PCB and replace the PCB with Artemis. I solder the wires of one motor to the motor driver and power the motor driver with external power supply to conduct spin experiment.

As the code shows, the wheels should spin in one direction for a second, stop for a second, then spin in the other direction for a second and stop for a second.

The video shows the wheels perform exactly as expected.

After ensuring there is no connection error between Artemis and motor driver, the Ground & Vin wires on motor driver are soldered with the power supply wires on the robot, at the same time, the Ground & Vin pins on the other motor driver are soldered in serial, therefore both motor drivers can powered by the battery now.

The video below shows single motor driver powered by robot battery

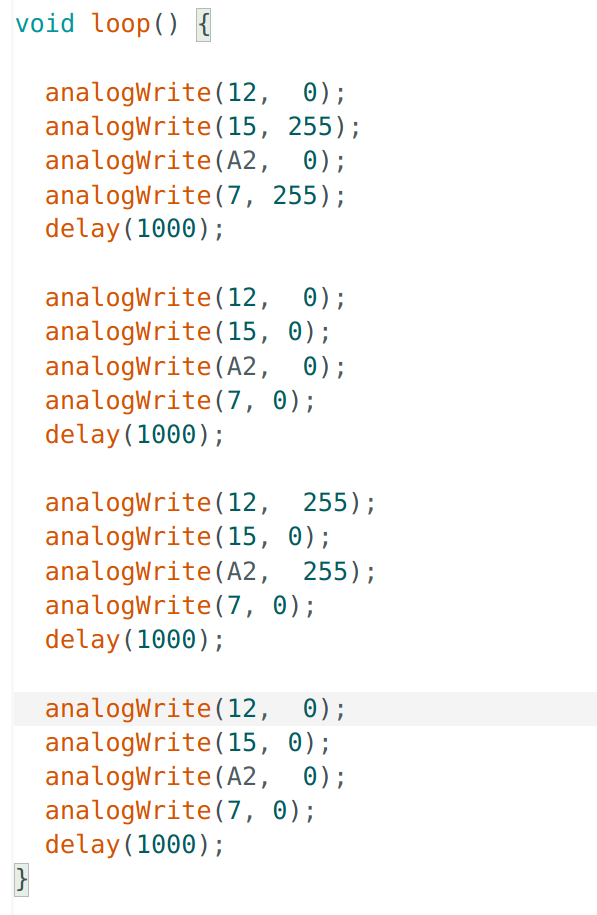

Similar to the first motor driver, the input pins of second motor driver is now connected with Artemis side and the output pins are connected with the wires from the other motor. Now two motor drivers control two motors using different PWM signals respectively, while they share the same power supply. The following codes are used to test both motor drivers.

The spinning pattern is just the same as the way single motor does. The video below shows powered by batteries, both sides of wheels spin as the code defines.

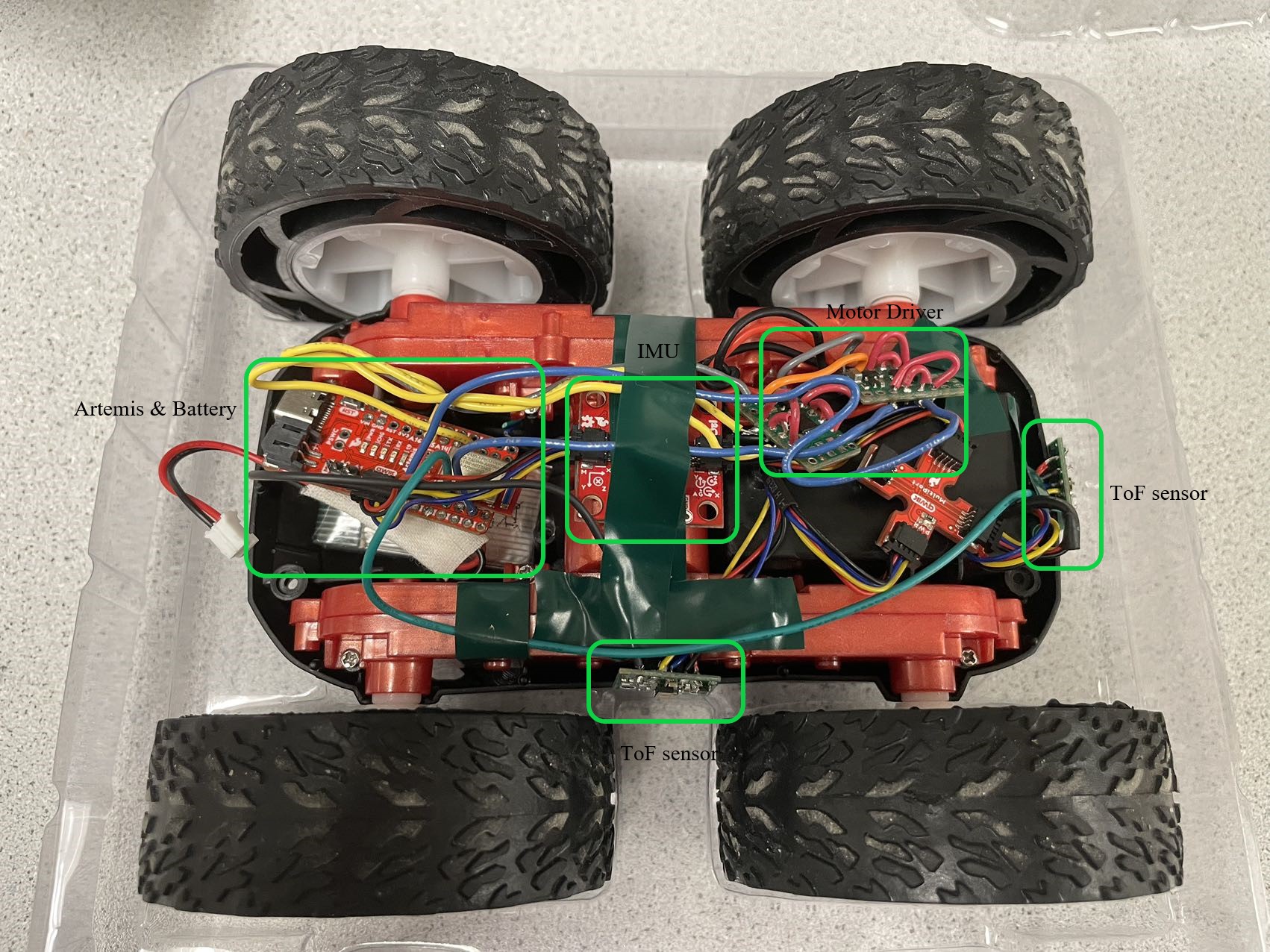

After testing both motor drivers are working properly, components from previous labs including IMU and ToF sensors are all configured within the car as the picture below demonstrates.

Lower Limit PWM Values

By conducting several times of experiments, I found that to make my robot start from the rest on the carpet to move forward, duty cyle of PWM needs to be at least 18% to provide motors with enough power.

While if the robot needs to make a turn, it will counteract with even more friction and hence it needs higher duty cycle up to 60% to provide higher speed. The video below shows robot goes straight with 20% duty cycle speed and makes right turn with a speed of 60% duty cycle. Since the ground is carpet, the friction is much greater than the lab ground, hence the "make turn" duty cycle can be higher as well.

It needs to be noticed that because of the different ground friction and remaining battery energy, the lower limit PWM results can vary.

Straight Line Running

Since both motor drivers are connected in serial with robot battery, ideally their power should be the same, and hence the spinning speed for both motors are the same. While to further test if both motors are actually spinning at the same rate when their duty cycle of PWM input signal are the same, I set PWM duty cycle of both motor drivers to be 35 % to try to examine if the robot can run a straight line. As video shows, basically the robot can run in a straight line with acceptable deviation when distance becomes longer.

While as I increase the duty cycle to try to run the robot with a higher speed, I found the devitation becomes more considerable as video below shows. It is probably because the motors need fidderent time to accelerate to the demanding speed, i.e. the acceleration of two motors are different.

Open Loop Control

Eventually, we come to the final target of this lab: to achieve an open loop control of the robot. The robot is simply hardcoded to do several actions including go forward and backward, spin and turns, as shown in the video below.

The codes for my robot actions are demonstrated as following.

Additional Tasks

analogWrite Frequency Discussion

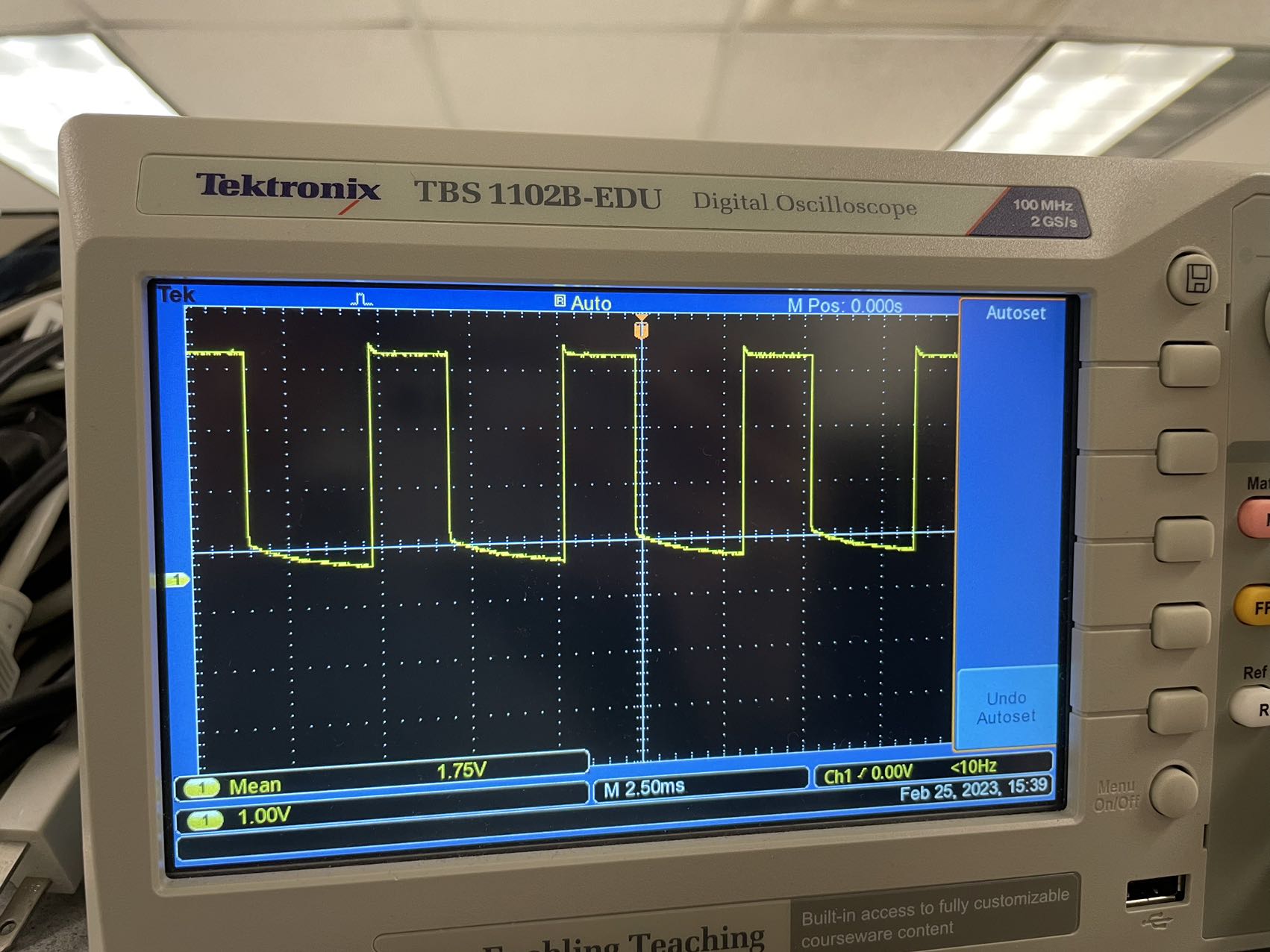

According to the PWM measurement by oscilloscope shown below, one horizontal block represents 2.50 ms and a period of PWM occupies about 2.2 blocks which is 5.5 ms. Therefore, on Artemis, the frequency of analogWrite function generates is about 182 Hz.

In lab 3, we have found that the sampling period of ToF sensors are around 20 ms which is much longer than PWM signal period. If the speed of motors are controlled based on data of ToF sensors, current frequency of PWM signal is fast enough to adjust motors' speed to react with obstacles.

While even faster PWM signals can make motors respond to our commands faster by changeing motors' speeds within a shorter time. This can help achieve more difficult stunts with requirement of faster responses and more precise control.

Lowest PWM Value Speed

To overcome ground friction, a higher duty cycle percent (20%) of 0.5 second is set to give robot a higher initial speed start from static state. Then, after conducting several experiments, it is found that the robot can move with the lowest duty cycle of 15%, as shown in video below.

What interesting is that, shown as the video below, by setting even lower duty cycle percentage to 12%, after the intial 0.5 second of acceleration, only one side of wheels are spinning while on the other side, we can clearly hear the motor spinning but seems its speed is not enough to drive the wheels. These cheap motors give different performances when they are fed by PWM signal with same duty cycle.

Texts and Videos by Zhongqi Tao